UNDERSTANDING CANNABIS EXTRACTS

A deep dive into the cannabis industry best practices and terminology.

A Brief History of Extracts

Today’s designer cannabis concentrates are the result of literally thousands of years of hash making and are best understood when viewed through the greater lens of human artisanship. “Hash” is generally known as the umbrella term that is widely applied to describe all cannabis resins that have been extracted or deliberately removed from their plant matter for refinement purposes, usually with the end goal of increased potency. The diversity of options consumers have is becoming endless – Leafly lists no less than 6,000 individual strains in its database, each with their own unique biological resin profiles and peculiar names. The incredible variety of different cannabis phenotypes, their effects, and consumption methods available to shoppers today in legal markets are difficult to truly appreciate without looking back into the past to see how far this ancient craft has come.

Glandular Trichome (Booth and Bohlmann, 2019) Phytocannabinoids accumulate in the secretory cavity of the glandular trichomes. Terpenes are responsible for the odor and flavor of the different Cannabis strains.

While some debate exists as to exactly how long-ago cannabis was first processed in one form or another, it was certainly during the historical period known as antiquity that our ancestors discovered the benefits of its use. Early sacred Hindu texts known as The Vedas which are thought to have been written between 2000 and 1400 BCE described cannabis as one of the five sacred plants (Gumbiner, 2011). Of the most potent forms of cannabis originating from the Indian subcontinent at that time are charas, which is an old-world form of hand rubbed hashish. Claudius Galen, a Roman doctor, provides perhaps the first written record of a specific cannabis preparation dating back to between 150 to 200 CE and the eminent Roman historian Pliny the Elder also made mentions of cannabis even earlier (Antoine, 2020).

The Verdas, Hindu.

Old-world Charas form of hand rubbed hashish from India.

Sometime around the 13th century but likely before hash making took another step forward in the middle east. Certain areas such as what is now Afghanistan, Morocco, and Lebanon are famous to this day for their bricked hashish, which was often cured and stored deep beneath desert sand. About 500 years later, William O’Shaughnessy is credited with introducing the contemporary west to cannabis from India in the late 1800s and is especially noteworthy for being one of the first doctors to scientifically note its potential use as medicine (Mukherjee, 2017). Not long thereafter cannabis tinctures and early extracts became popular commercial products in Victorian era England as well as the United States, which were prized for their anesthetic and calming properties. After cannabis was made illegal in the US in the late 1930s, it would take another half century before the inklings of present-day hash making techniques began.

Field of Cannabis, Morocco.

Lebanon bricked hashish.

As is the way with much innovation, it doesn’t happen on a linear scale, it happens exponentially at some point, and cannabis extraction procedures mirror this trend. The past 50 or so years have seen an explosion of progress in hash making. As early as the 1970s alcohol, butane, and other solvents were starting to become known as possible options for refining cannabis into more potent products. In the 80s and 90s, bubble hash quickly became popularized as a safer concentration method. Another decade passes and in the early to mid 2000s, open blasting butane hash oil then unseats bubble hash to become the dominant choice of making oils with all of the attending safety concerns that people today are all too aware of. In fact, solvent-based extraction techniques rose to the forefront during this time as the first legal medical and recreational cannabis markets started to emerge in America. These methods were largely borrowed from other large scale commercial industries such as agriculture and perfume making for their efficiency, not necessarily their quality. Extractors could take just about anything and make a usable oil to be sold. Regulatory frameworks that demanded safety were quick to emerge once it became clear that the demand for cannabis concentrates was only going to grow, which is a trend that continues to this day unabated.

Butane Honey Oil better known as “Butane Hash Oil” aka BHO, 2010.

6 Star Full Melt Pressed into a what is known as a Flag, 2013.

With increased demand came ever larger machinery to produce cannabis oils, many of which focused solely on throughput and the ability to process any plant matter which contains cannabinoids, good or bad. Solvents of all varieties were tested and a handful have now been vetted for widespread use in most places, which include CO2, ethanol, butane, and propane. What no one predicted however was that humble ice water hash washing would be catalyzed by the discovery of rosin making around 2014 by Phil Salazar, who goes by Soilgrown, when he borrowed his girlfriend’s hair straightener to squeeze a bud out of curiosity. The eureka moment followed almost immediately as traces of golden oil began oozing out. The combination of gently pressing isolated, intact trichomes between heated plates through filtration media to express their resins has evolved so rapidly to become the undisputed connoisseur extraction method it almost defies belief. This modern renaissance of artisan hash making is where our story today begins.

Solvents and Solventless

Stepping into a dispensary these days can be an overwhelming experience for many: the immense variety of different types of flower, edibles, concentrates, vaporizers, tinctures, topicals, capsules, and even beverages is a lot to take in. What is even harder to discern is what is being used to give extracted or infused products their desirable effects. The various hash oils used for concentrates, vaporizers, and ingestibles are often purposefully obfuscated or at best are unclear to most consumers in regards to how they are actually made at the lab. Like the legion of processed products found at grocery stores, this is because most businesses don’t really want you to know how the sausage is made. What astute purchasers today tend to look for however is whether or not what they plan to purchase is made with solvents or solventless hash.

Commcan dispensary in Massachusetts.

Dr. Jolly dispensary in Oregon.

Fundamentally, the process of extracting the resins from cannabis and hemp boil down to two approaches: chemical dissolution or mechanical separation. The first example is the use of different solvents which through a process of chemical dissolution capture a variety of useful phytochemicals and then reconstitute them through purging of the original solvent into a potent, usable oil. These fairly elaborate processes when done correctly enable processors to collect molecules that have immense commercial value from the cannabis plant while leaving everything else behind. Solvent-based processing offers laboratories a variety of advantages, including unmatched throughput, minimal labor requirements, as well as the critical ability to take plant matter with contaminants such as mold or bugs and turn it into something profitable.

Removal of impurities and residual solvents using steam distillation equipment that activates THC in the process.

Active THC Distillate can be combined with mct oil to create a sublingual drop.

The vast majority of cannabis oils today are made with the help of solvents due to these efficiencies, but most customers are none the wiser. It should be mentioned that while plenty of solvent derived hash oils are made with cannabis that will pass testing on their own, many still would not. Whenever you see distillate oil, butane hash oil (propane is also sometimes mixed in), CO2 oil, or ethanol oil on a packaged product label that is your indicator as to which exact solvent was employed. Each solvent has its own merits for extractors depending on what kind of material they are working with and what their ideal end result is. Virtually all of the viscosities and textures of concentrates or cannabis oils can be made in either a solvent-based or solventless manner, but taste preferences over the years have driven what processors put out. These trends are ever evolving and processors are constantly adjusting their product lines to try and meet current palettes.

Solventless extraction techniques on the other hand rely upon what is known as mechanical separation. Instead of dissolving the plant’s trichomes that contain the majority of its resins, the goal is instead to physically detach them and keep them intact for sale as-is or more commonly to be further refined by being pressed into rosin. The main exception to this is in the case of flower rosin, which is simply resin expressed directly from whole dried flowers, but unfortunately this practice does not enable laboratories to create a truly premium end product. Regardless, all solventless extraction depends on elemental forces to work. This can happen in a few ways, from sifting dry plant material across fine screens to washing freshly harvested and never dried cannabis in a bath of ice and water. If you’ve ever seen “live” resin or rosin and wondered what that meant, this distinction of using undried cannabis in an extraction process is what gives it that special designation. More on that in a moment.

Mechanical separation of trichome heads from freshly frozen live cannabis biomass process using cold water, ice, and hand paddle techniques known as “Hand Washed”.

Separated trichome heads from freshly frozen cannabis biomass using ice water agitation and freeze dryer technology to preserve color and flavor.

One thing consumers should keep in mind is to take notice when the term “solvent free” is used, which is often confused even by those in the industry at times with “solventless”. Solvent free concentrates are those which were originally made with one solvent or another, but which have been purged sufficiently to contain no testable trace amounts of it. Some manufacturers will try to purport that their product is solventless when in fact it is solvent free. This distinction is important because again, those products are made via dissolution and carry the same considerations that solvent-made ones do.

BHO Shatter purged under vacuum to remove residual solvents. Under 15 PPM.

Solvent-free Distillate. Butane & Pentane extraction with post processing distillation to remove all residual solvents.

Making a high quality live ice water hash is often the first step of many to make a topshelf live rosin, live rosin vaporizer cartridge, or a solventless infused edible. Products on shelves that are made this way tend to retail for significantly more than what their solvent-based alternatives do, and for good reason. First off, harvesting with the intent to freeze instead of dry enables cultivators to capture the unique organic fingerprint of each particular plant at peak ripeness in order to preserve as many of its delicate, highly volatile terpenes as possible. This has to be done rapidly, as the plants are quickly defanned, bucked, and their inflorescences (science lingo for flowers) are then frozen. Highly skilled harvesters complete this in under 15 minutes, which is a sight to behold.

Live cannabis biomass being prepared to be frozen within 15 min of harvest.

Freshly frozen cannabis biomass.

Once ready to wash, the trichomes are made brittle by the cold temperatures of the ice water bath which is then agitated through manual or mechanical mixing. After the detachment process the tiny fruits of the cannabis plant are filtered, graded, and freeze dried. The best of the best of them may be sold as “full melt”, which means that the resin and trichome shell dissolve completely upon vaporizing which indicates an exceptionally pure product. In most other cases, the carefully freeze dried trichomes are pressed in a variety of ways to make all kinds of different hash rosins or recombined to create the correct viscosity for a vaporizer cartridge. The level of technical details and chemistry required to perform advanced solventless processing is an art in and of itself – the right temperatures, pressures, post chilling or warming, and base constituent separations all require extreme care to do well.

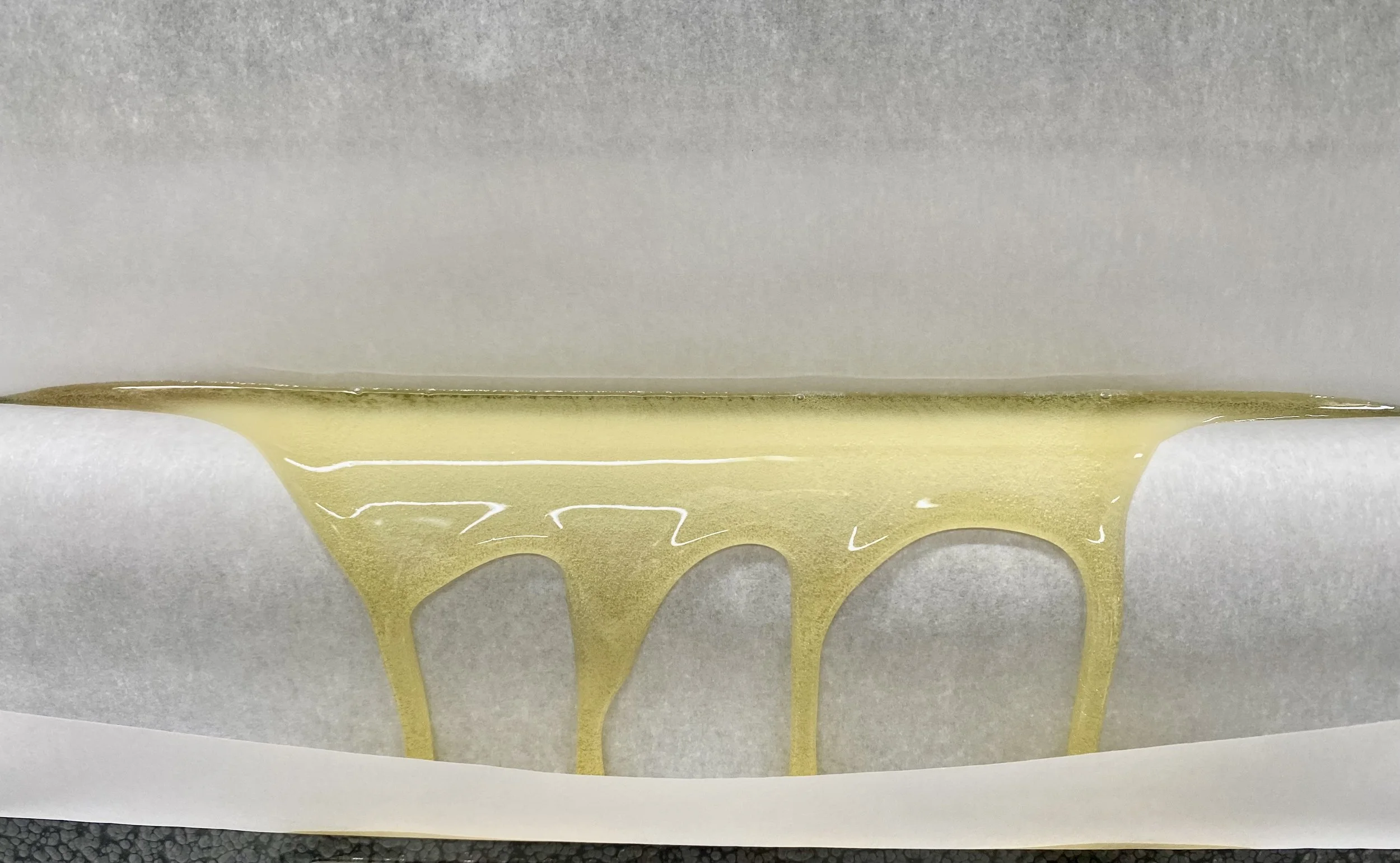

Live Rosin created using a Rosin Press. The oil is created by expressing the separated trichome heads under high pressure using low heat to extract cannabis compounds from within the cellular wall or “skin” of the trichome heads.

Live Rosin collected in a jar and stored in a cool room to naturally allow the oil to homogenize. Terpenes are lighter than cannabinoids so they naturally float to the top as seen by the amber oil residing at the top of the jar.

Solventless extraction from beginning to end is openly unforgiving and requires keen attention to detail on the extractor’s part. This starts with first selecting and testing cannabis that possesses an ideal capitate-stalked glandular trichome type which will detach most easily, a flower structure that is not too dense to offer proper surface area to detach from, and rich enough resin content to make the entire endeavor worthwhile. Perhaps one third or less of common strains fit the profile, with far fewer than that making the cut for larger batches worth a hash maker’s time consistently. Constant strain type testing is conducted to find the winners for solventless whose genetics end up being worth their weight in gold to businesses.

GMO in early maturity flowering stage. A trained eye can spot proper bud structure, resin production, and type of resin glands produced by the genetics and cultivation techniques.

Big and dense bud structure does not necessarily equate to high yielders when using ice water agitation methods.

Cannabinoids, Terpenes, Flavonoids

Throughout the piece a number of terms have been repeatedly mentioned that so far remain unexamined but deserve to be, especially for the lay reader who wants to know more about cannabis. Those terms are cannabinoids, terpenes, and flavonoids, which together constitute the most important organic molecules that these prized plants contain in varying quantities. Thankfully, you don’t have to hold a degree in biochemistry to be able to understand them and appreciate what these near magical compounds can do. To simplify things, here is how to think of each in turn.

Cannabinoids: these are the chemicals responsible for interfacing with your brain’s endocannabinoid receptors which create the highs and effects of cannabis or hemp. Think THC, CBD, CBG, CBN, THCV… the list goes on and on. Most of these chemicals exist in an acidic form prior to being decarboxylated (THCA may be familiar), which means a conversion via heat to become biologically active. This is why eating raw cannabis does nothing but make your teeth sticky but a 450°F vaporized dab of oil gets you high.

Terpenes: appetizing aromas and flavors are created with combinations of terpenes, which are present all throughout nature in plants, fungi, and are even made by some animals. These special molecules are what make different strains smell like everything from pine trees to distinct fruits such as oranges or strawberries. Terpenes are especially prized because their unique combinations that different cannabis phenotypes produce are fleeting. Make sure to read our deep dive on terpenes here if you want to learn more about them!

Flavonoids: last but certainly not least are flavonoids, which are responsible for pigmentation and act as powerful antioxidants that provide anti-inflammatory properties to help regulate healthy cellular activity. While commonly found in all kinds of plants and foods, cannabis has a handful of unique flavonoids known as cannflavins. Anthocyanins are another class of flavonoids worth knowing about, since they are what give purple hued strains their distinct appeal.

When they say variety is the spice of life, cannabis’s genetic diversity holds delightfully true to this maxim. Just about every kind of flavor profile, aroma, and possible effect from hyper uplifting to deep sedation is possible depending on each plant’s particular combination of phytochemicals when combined with each individual’s unique neurochemistry. Scientists so far have discovered at least 500 components within cannabis plants, over 104 individual cannabinoids, 120 different terpenes, and 20 or more flavonoids present in Cannabis sativa with undoubtedly more discoveries on the way (Finlay et al., 2020) (Lafaye & Brousse, 2017) (Bautista et al., 2021).

An especially fascinating link between extraction and the cultivation process itself is how different growing environments can affect each plant’s production of the C’s, T’s, and F’s. In our experience, the various types of lighting systems used can have a significant change in the outcome of a critical factor in solventless extraction: trichome shell density. At first pass this might sound like minutiae that is of little interest, but hear us out. Cannabis, like all plants of course, requires light as its primary energy source to grow. The many types of light they use range from those directly of the sun itself, to high pressure sodium bulbs, as well as LEDs. Each source has similar applications and varying opinions of utility from cultivators, but these light sources can change the way their tissues appear (flavonoids) as well as how their flower to resin ratios are ultimately developed. The same exact strain cloned three times will come out differently depending on the light it was grown under, along with many other environmental factors. When your manufacturing methods are the same but the outputs come in many colors, it’s likely that the light type used is why. Which is all a long way of saying bag appeal plays an important role in concentrates too, especially solventless ones.

Traditional hoop house or green house style of cultivation utlizes sun light and controlled environments.

High Pressure Sodium bulbs used for indoor cultivation during flowering cycles to target specific light spectrums that promote resin production.

Solventless Products

We’ve talked a lot about the many of the individual aspects of solventless products that make them special, but have yet to break down all of the options people have when picking just the right one for them. Well, good news. It’s time. The kaleidoscope of choices across how they’re consumed and which strains are used is vast, but here’s a great template to start with so you can find which one might be best for you. Whether you prefer vaporizing discretely or openly or want to eat your solventless, there’s something out there that suits everyone.

Solventless Extracts

● Full Melt or Ice Wax Hash: often the connoisseur’s choice, these are the finest trichomes the cannabis plant has to offer and many strains do not create “melt” as it’s known. When properly frozen and stored it resembles sand, but quickly homogenizes and greases up at room temperature. The Star Rating system (3-6) was developed to determine the quality of the “melt” and purity of the isolated resin glands; moreover, trichome heads are also classified in by their micron size ranging from 220u-25u. Often times these notations will be proudly presented on the labeling of the product such as 90u-120u / 6*. Full Melt should be packaged and stored at all times between 0f-41f.

90u-159u Trichome heads separated using ice water extraction methods by Blue River Terps.

● Fresh Press: live hash rosin that has been pressed and is intended to be sold as is. Fresh press is not homogenized and augments quickly at room tempature by transferring from fruit-leather shards into a clear oil that eventually will turn into a fairly uniform opaque smooth extract. The key to preserving this extract for the consumer or patient is to immediately store and package the fresh press inside a cold room environment. The extract should be stored at all times at 41f when not being used for consumption.

Fresh Press 90u-159u GMO by Blue River Terps. Photography by Ryan Smith.

● Cold Cure: live hash rosin which has been pressed, placed in a sealed jared, and chilled over a period of at least 1 week to provide an especially flavorful buttery to a cake batter type texture. Often times this product is made from a full spectrum of trichome heads ranging from 45u-159u unless it is noted on the labeling or packing with any select range from 70u-159u. A premium select range will be noted between 90u-159u. This extract should be stored at all times at 41f as this type of extract will begin to evaporate terpenes at room tempature leaving behind a white dry chalky texture.

Cold Cure Live Rosin Mimosa by Blue River Terps 2020. Photography by Ryan Smith.

● Wet Badder: live hash rosin which has been pressed, placed in a sealed jared for curing, then manipulated with friction or slight heat to homogenize the extract to be more shelf stable. Manufactures have different techniques that they have developed over the years and is often times kept close to the chest from their competitors. Often times this product is made from a full spectrum of trichome heads ranging from 45u-159u unless it is noted on the labeling or packing with any select range from 70u-159u. A premium select range will be noted between 90u-159u. The extract should be stored at all times at 41f when not being used for consumption.

Blue River Signature Live Rosin Wet Badder 90u in collaboration with Impressed Cannabis. MA 2023

● Jams: Live Hash Rosin which has been gently heated in a sealed jar to slightly “participate” micro THCa crystals from the present terpenes in which creates an extremely aromatic, stable, and potent extract that resembles a fruit purée sauce or jam. The benefit of this type of extract is the higher shelf stability but should always be keep in the refrigerator when not consuming it at home. Often times this extract is made from a full spectrum of trichome heads ranging from 45u-159u unless it is note on the labeling or packing with any select range from 70u-159u. A premium select range will be noted between 90u-159u. The extract should be stored at all times at 41f when not being used for consumption.

● Live THCa: Although it lacks the high terpene content that some other hash rosins do, solventlessly derived THCA offers the highest potency extract that is highly palliative. This extract is generally used as a bowl topper, infused with flowers in a joint or blunt, but can also be used as a stand alone extract, combined with other extracts, reshaped into 3D hash art by heating it in a mold to semi-decarboxylate THCa into THC, or used in at home edible recipes.

Live THCa by Blue River Terps 2019. Photography by Ryan Smith.

● Solvenltess Diamond Sauce: This extract can be created be semi-activating Live THCa and Live Rosin separately then re introducing the two extracts as one. This type of “designer” extract can be appealing to connoisseurs because it presents a duality of flavors, effects, and textures. If done right, this extract is shelf stable but should always be kept in the refrigerator between 34-41f for long term storage.

Solventless Diamond Sauce by Blue River Terps 2018.

● AMST: Advanced Mechanical Separation Techniques, better known as AMST aka “deconstructed” extracts, was popularized by the Blue River™ team. This technique uses a base Live Rosin, often a premium select 90-159u, that relies on 1-4 different type of mechanical extraction techniques to improve purity, increase terpenes, target designer effects, alter consistencies, and improve overall stability. Extracts that utilize AMST include: Live THCa, Live Rosin Sauce, Jelly Sauce, Torrone, Pioca, Flan, and Hash Art.

AMST used to separate or “deconstruct” Live Rosin into THCa, THC, Terpenes, without lipids, waxes, or flavonoids.

Solventless Vaporizer Cartridges

● Live Rosin: Made with mechanically derived cannabinoids and terpenes. They can come in different viscosities but are prized for their quality, effects, and flavors above other chemical vaporizer varieties. The extract is made by semi-activating or fully activate Live Rosin in a sealed jar using different heat sequences over time. Manufactures have developed their own unique process over the years. The quality of the Live Rosin oil is dependent on the grade of trichomes used to make the Live Rosin extract. A premium grade Live Rosin batch will be identified in the range of 73u-159u. A full spectrum Live Rosin will fall in the range of 45u-159u. The overall Total Active Cannabinoids and Terpenes % upon receiving a 3rd party lab COA (certificate of analysis) is the hash makers “score card” for evaluating their skill level. The uniqueness of the flavor profile and the results of the certificate of analysis are a big part of the customers decision to buy different types of Live Rosin Vape products.

Solventless Ingestible

● Edibles: creative chefs can infuse full spectrum solventless hash oil into any edible imaginable. Think beyond brownies because nothing is off limits with solventless edibles, including water soluble options that can be added to any beverage.

● Capsules: if you’re after something easy to consume that still offers the dynamic effects of solventless, look no further. Multi-cannabinoid capsules are common and can offer all kinds of health benefits.

Strain Specific, Vegan, Gluten-Free, Low Calorie, Solventless Live Rosin CBN powder capsules. Photography by Ryan Smith.

References

Antoine, M. -. (2020, September 22). History of cannabis and the endocannabinoid system. NCBI. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7605027/

Bautista, J. L., Yu, S., & Tian, L. (2021, February 18). Flavonoids in Cannabis sativa: Biosynthesis, Bioactivities, and Biotechnology. NCBI. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7931196/

Finlay, D. B., Sircombe, K. J., Nimick, M., Jones, C., & Glass, M. (2020, March 25). Terpenoids From Cannabis Do Not Mediate an Entourage Effect by Acting at Cannabinoid Receptors. Frontiers. https://www.frontiersin.org/articles/10.3389/fphar.2020.00359/full

Gumbiner, J. (2011, June 16). History of Cannabis in India. Psychology Today. https://www.psychologytoday.com/intl/blog/the-teenage-mind/201106/history-cannabis-in-india

Lafaye, G., & Brousse, P. (2017, September 19). Cannabis, cannabinoids, and health - PMC. NCBI. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5741114/

Mukherjee, S. (2017, April 19). W. B. O'Shaughnessy and the Introduction of Cannabis to Modern Western Medicine. The Public Domain Review. https://publicdomainreview.org/essay/w-b-o-shaughnessy-and-the-introduction-of-cannabis-to-modern-western-medicine